Open/Short Analysis

Optimal netlist analysis tools in the industry: Netlist Compare, Network Analysis, Open Short, Electrical Testing, Back Drill Calculation, Short Pad, Open Short Circuit Reading Best Solution

Feature:

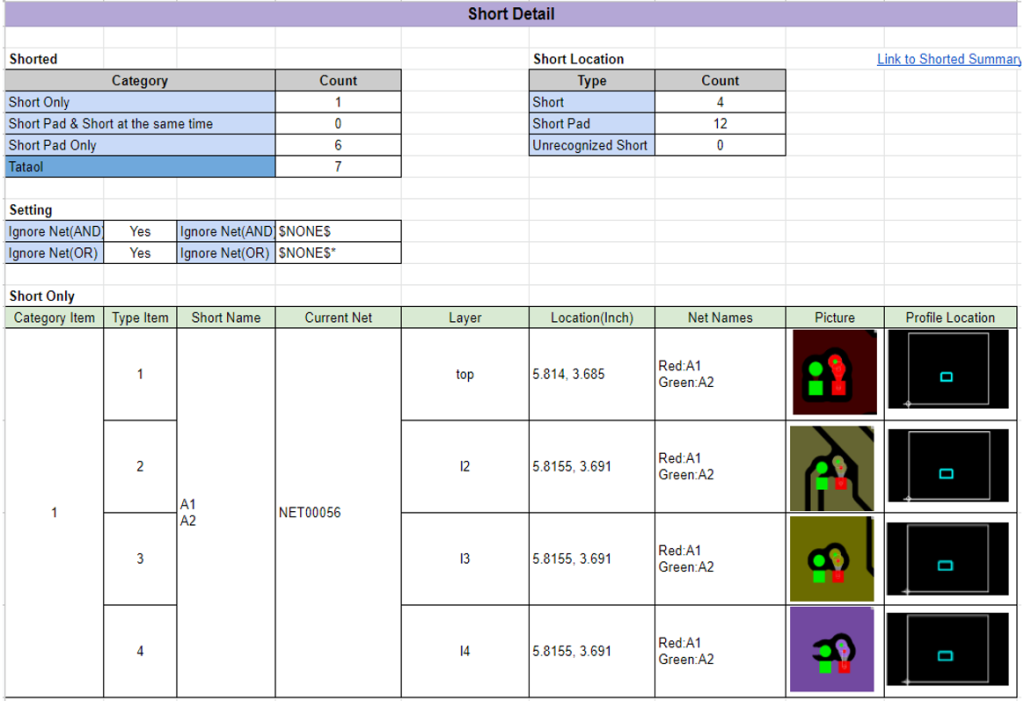

1. Quickly pinpoint the reason for open/short circuits in high readability so that users can easily “comprehend” the problem.

2. Auto distinguish between short pad and real short through Zero ohm resistance (Short Pad) filtering mechanism instead of distinguishing them manually.

3. Automatically output reports with related texts and screenshots to make the report easier to read.

4. Classify net names without signals precisely ($NONE$, N/C network).

5. Calculate the net relation of NPTH in the back drilling design.

Feature comparison in the same industry

| CAMPro | Other Similar Software | |

|---|---|---|

| Analysis results readability | Easy to read |

Experience Required |

| Zero ohm resistance (Short Pad) countermeasures | Built-in filter mechanism | Additional development of Script/Skill filter |

| Analysis Report |

Screenshots, texts, parameters

|

Text only, users must browse the interface |

| $NONE$、N/C Net | Each group can be classified. Net: N/C, $NONE$ |

Can not be classified |

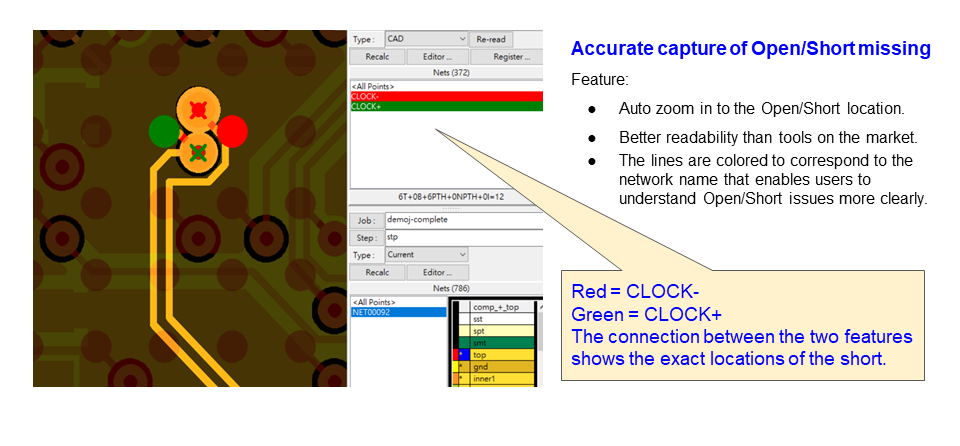

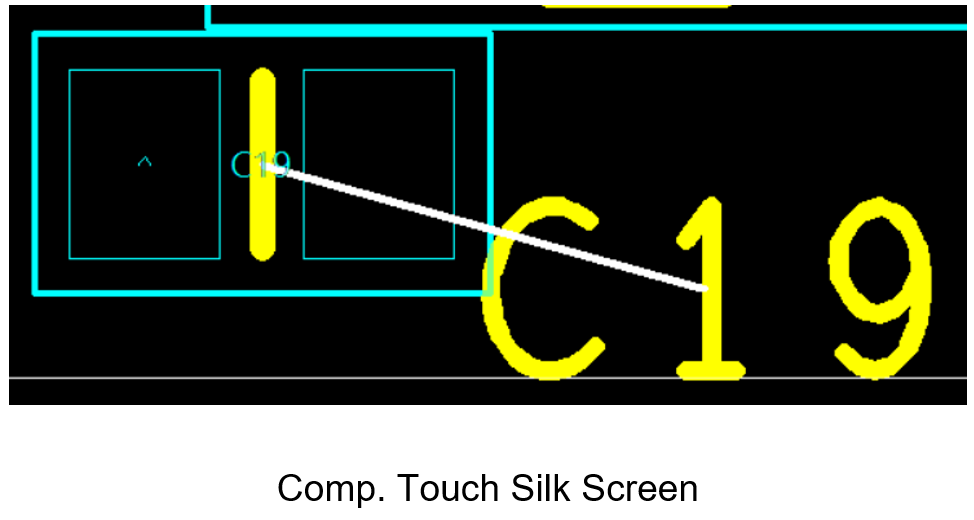

1. Quickly pinpoint the reason for open/short circuits in high readability so that users can easily “comprehend” the problem.

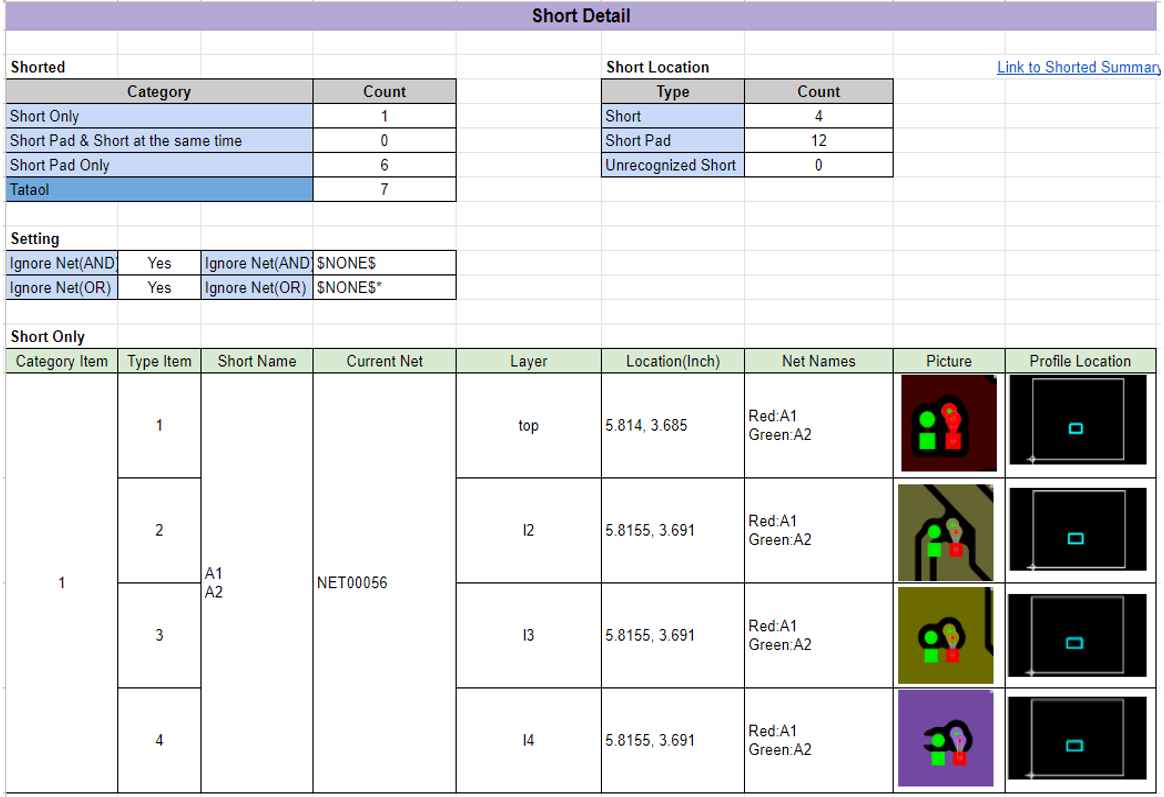

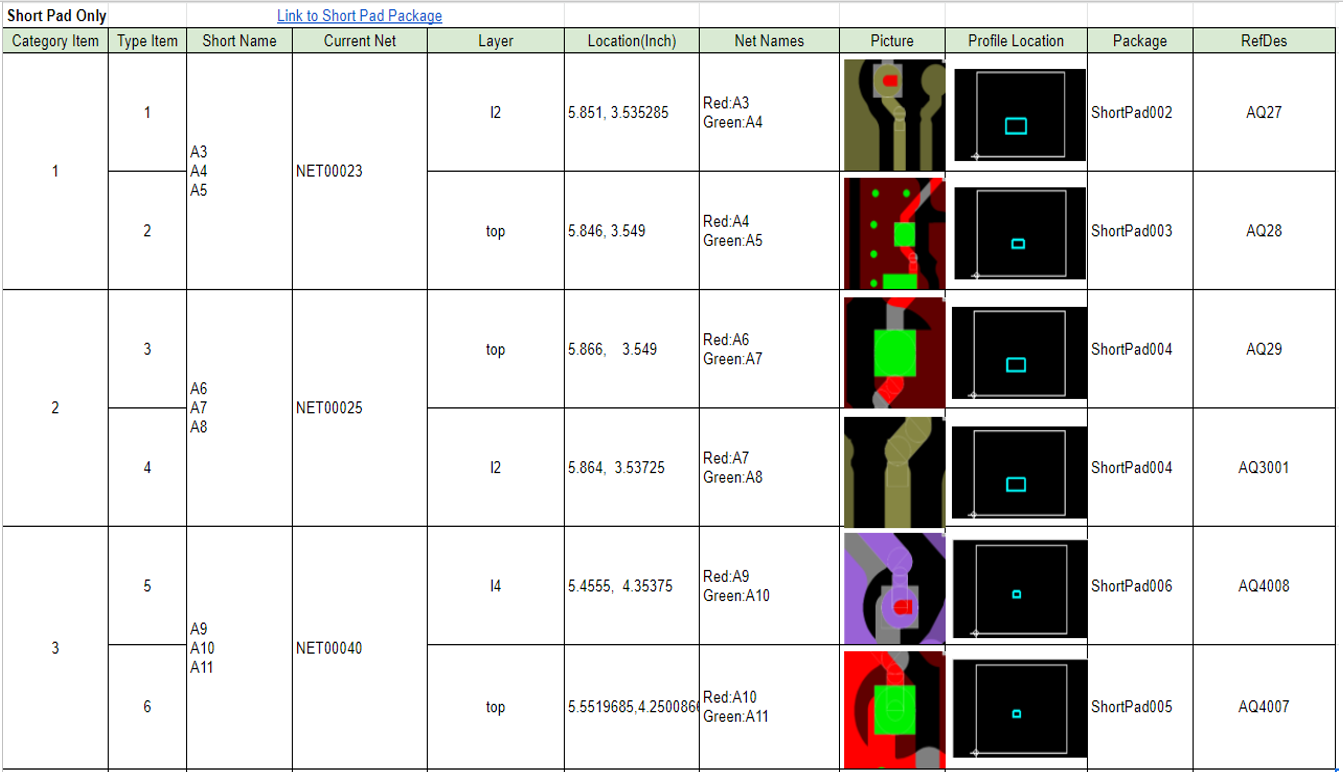

2. Auto distinguish between short pad and real short through Zero ohm resistance (ShortPad) filtering mechanism instead of distinguishing them manually.

3. Automatically output reports with related texts and screenshots to make the report easier to read.

No longer need to read reports that are difficult to understand,

The appended pictures are combined with colors to distinguish different net.

Short circuit issues can be understood without much field experience.

Real short and intentionally short pad design is illustrated in the output report.

4. Classify net names without signals precisely ($NONE$, N/C network).

5. Calculate the net relation of NPTH in the back drilling design.

Integrate with CAD Tool

CAMPro is an analysis tool for CAD design that aims to make the user use it easily and quickly. The common analysis functions are directly embedded into the CAD tool, which can help the user to run the analysis without too much learning.

Feature comparison in the same industry

| CAMPro | Other Similar Software | |

|---|---|---|

| Time to get started | Fast |

More learning time required

|

| File Conversion | Direct cross probe to CAD Tools to convert files | Convert files manually |

| Customized shortcut function | It can be customized to fit the needs of the user. | Not supported |

Video demo:

Gerber Version Compare

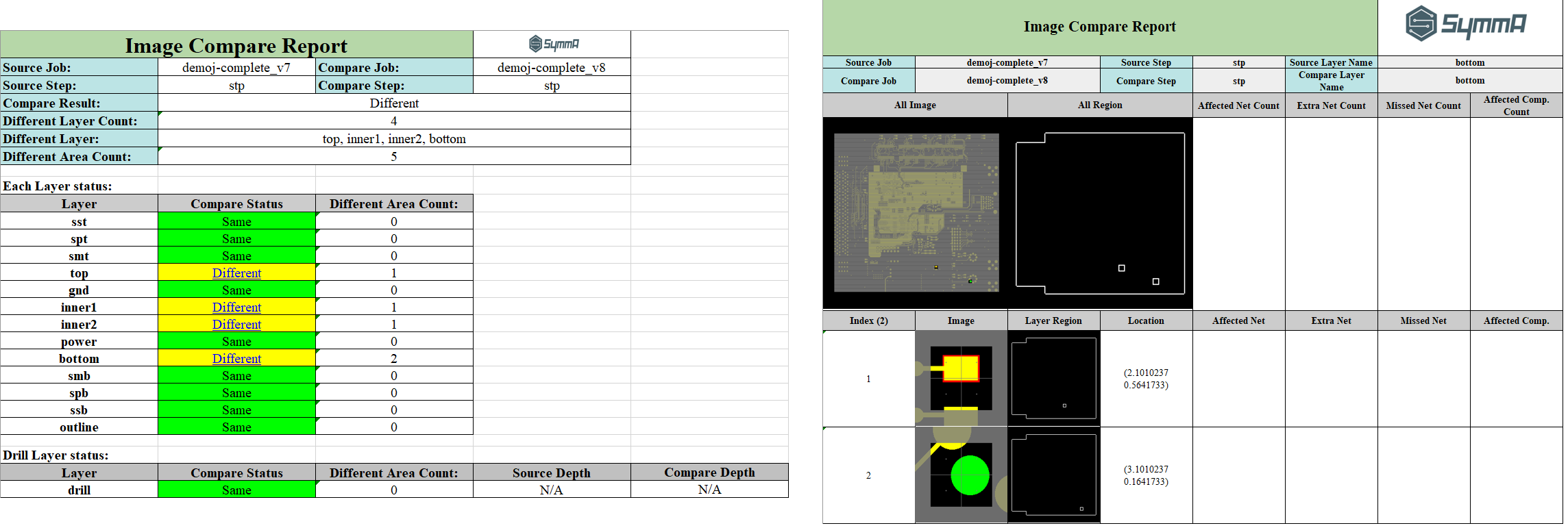

Advantages of version comparison:

- Skip the tedious process of manually input and output Gerber.

- CAMPro automatically gathers 100% of the differences without the need for manual comparison.

- Embedded in the CAD Tool, one click to compare different versions.

- Automatically output a comparison report with clear screenshots and the coordinates

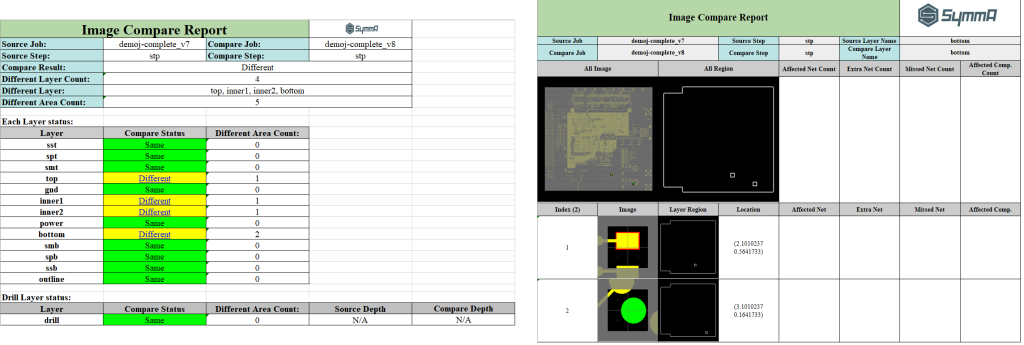

CAMPro version compare report:

CAMPro version compare report:

Gerber Version Compare in the illustration:

Demo video:

CAMPro Version Compare – Compare different versions in the CAD Tool

CAMPro Version Compare – Analyze differences between different versions in CAMPro

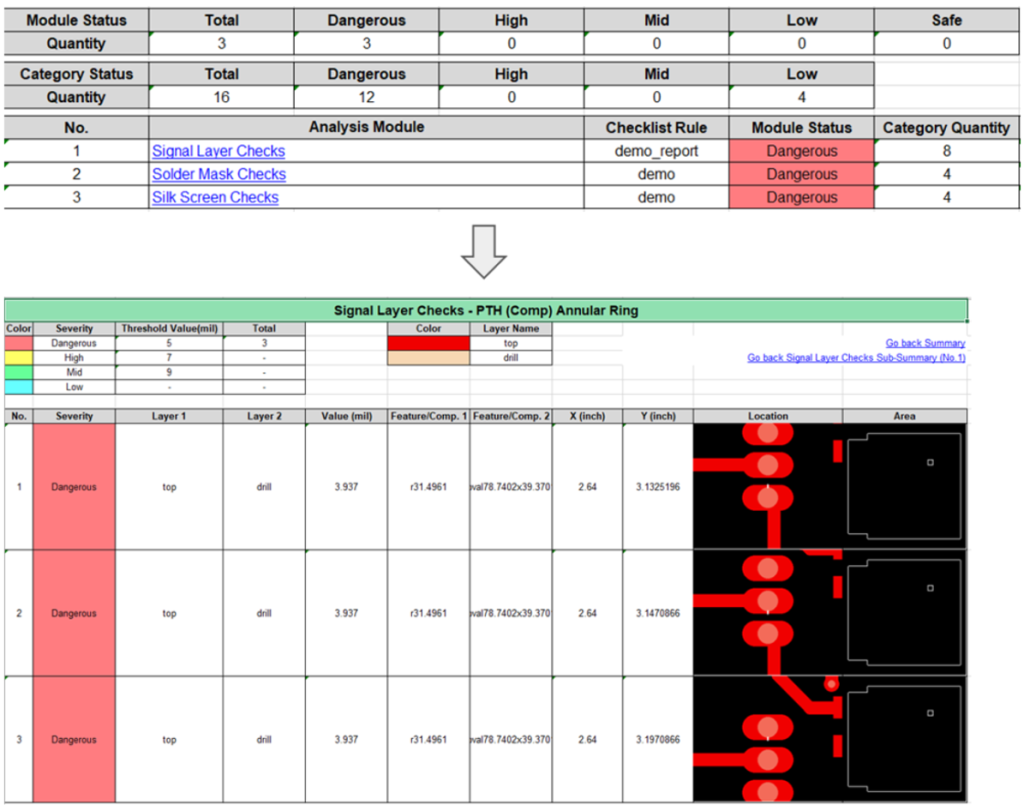

Auto Output Report Tool

In addition to analyzing the manufacturability and assemblability of the production format, the mainstream Gerber analysis software must enable users to output the analysis results into reports with high readability.

Feature comparison in the same industry

| CAMPro | Other Similar Software | |

|---|---|---|

| Readability | High | Lower, users must browse the interface |

| Format |

Screenshots, data

|

Only data |

| Content | Data summary and structured descriptions | Row Data description |

Open Short Report

DFM Analysis Report

Version Compare Report

Net Tracer Report

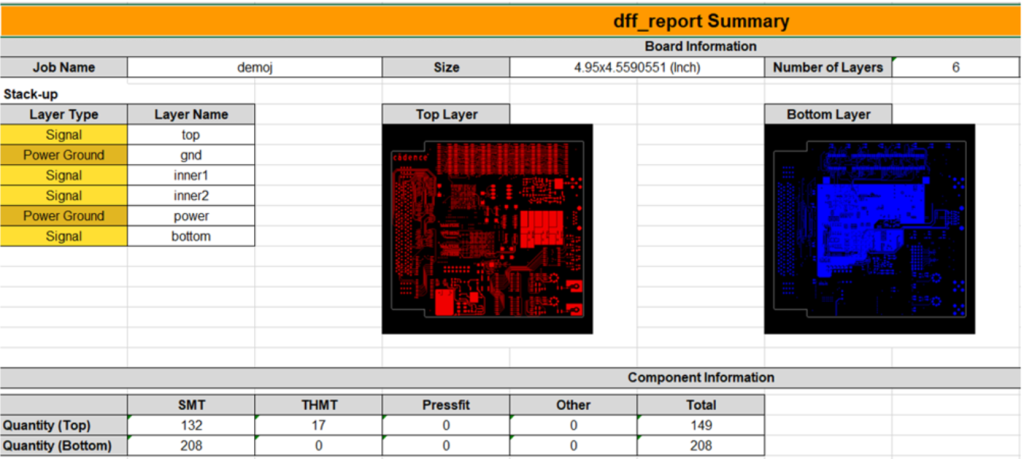

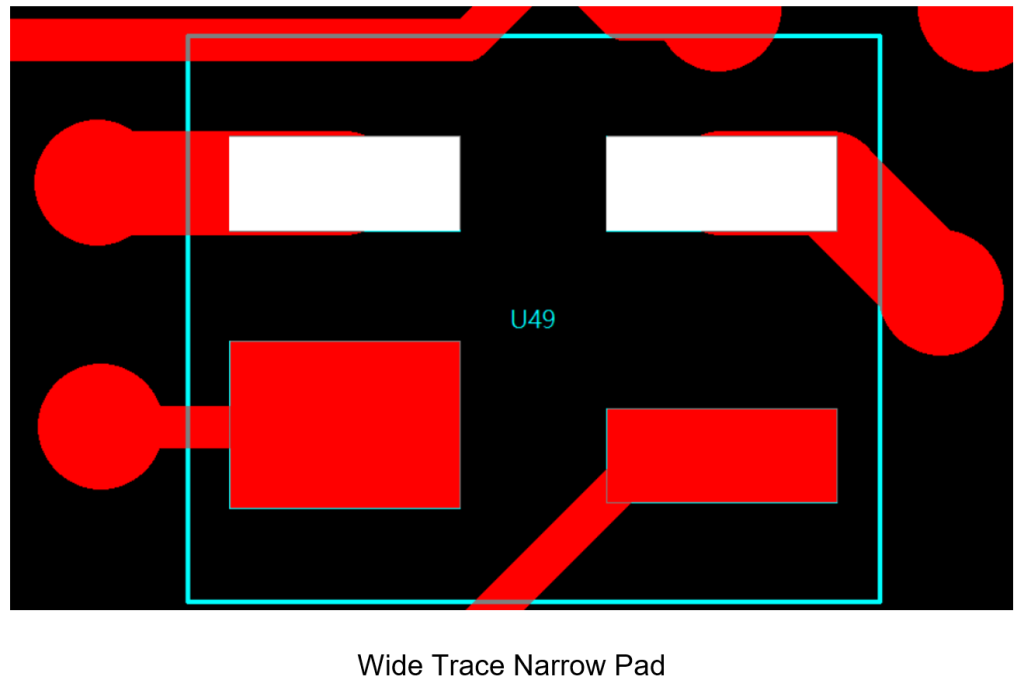

DFF (Design For Fabrication)

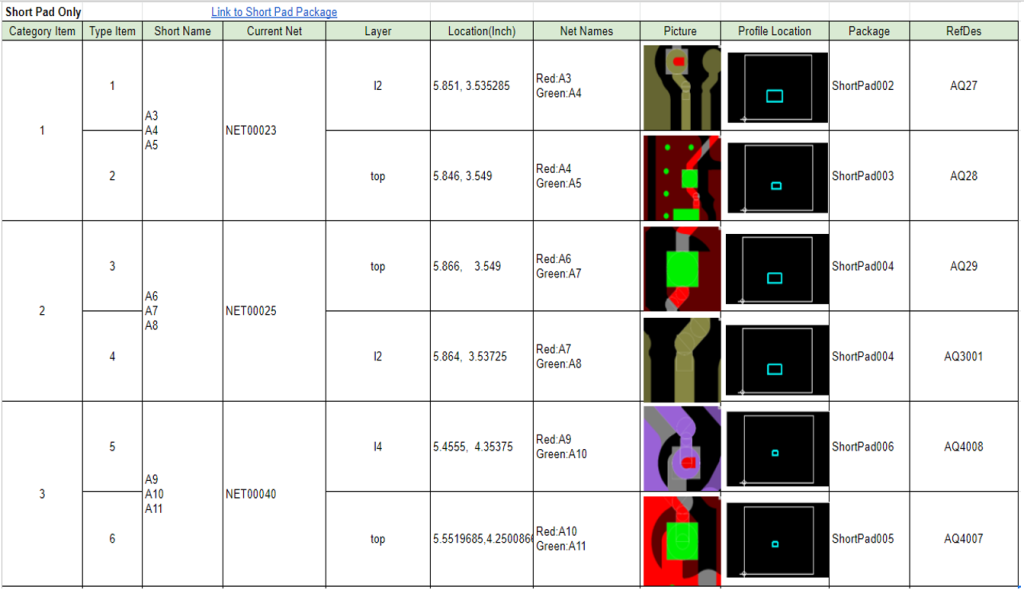

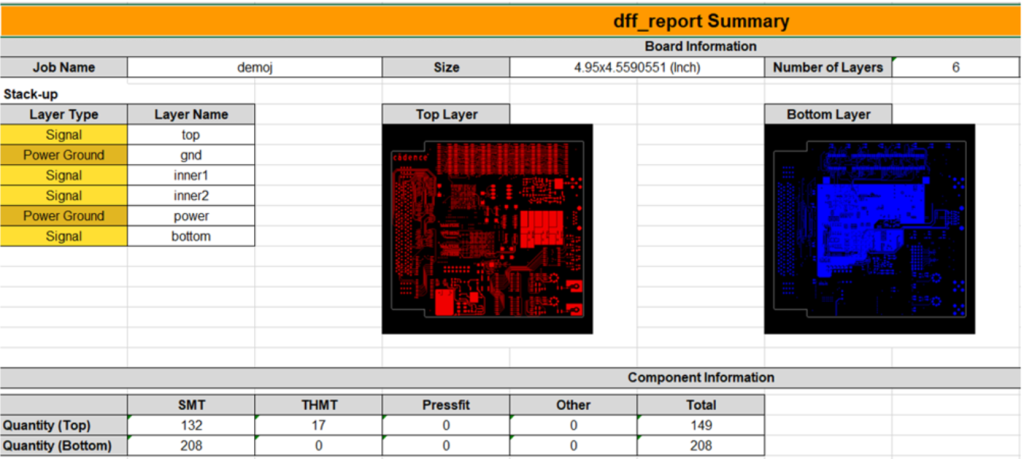

Before putting PCB into production, a comprehensive analysis of the manufacturability of the product is conducted following the design data and taking into account the actual processing and production process requirements. In the meantime, it enables one button to output the analysis report quickly.

CAMPro DFF Feature:

- Built-in analysis templates that R-PCB/HDI used all over the industry. It makes CAMPro DFF approachable without the need for introduction and a lot of training.

- Output the analysis report in just one click, saving the time of taking screenshots manually.

- The report is easy to read and contains general reviews, images, coordinates, and other information.

Turn “actual production problems” into “analysis list”

One button to output a comprehensive analysis report

Board information

Video demo:

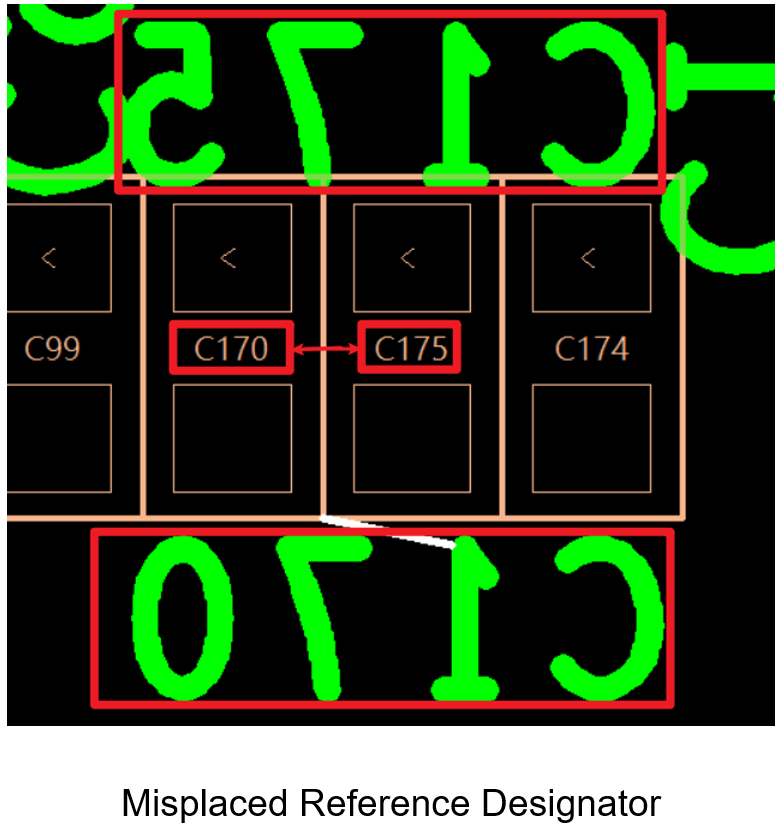

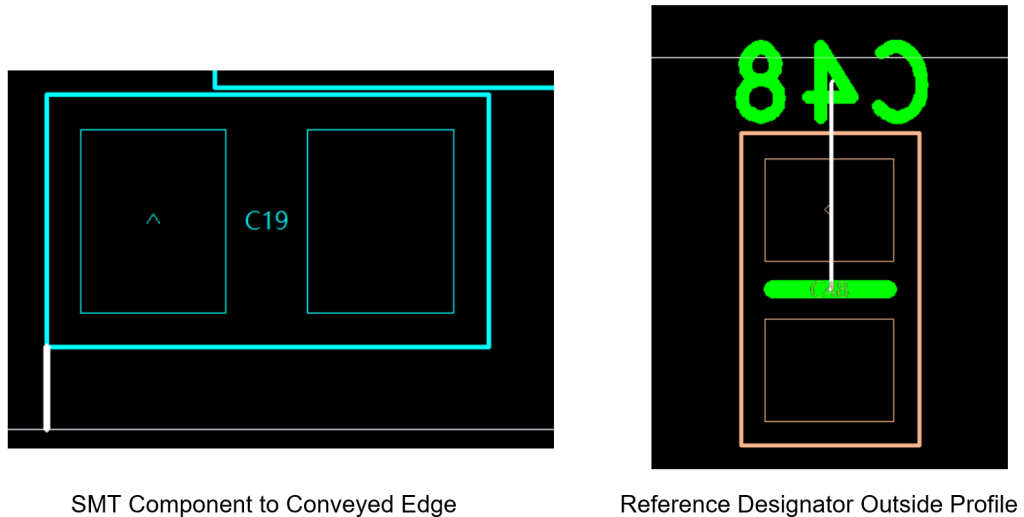

DFA (Design For Assembly)

During the PCB manufacturing process, Assembling components is usually the most time-consuming and expensive process. The purpose of PCB assembly is to correctly place components on a PCB board.

For the Assembly process to complete successfully, you need to know as much as possible whether the assembly is applicable in future assemblies.

CAMPro DFA Feature:

- The components can be customized to be classified, and the components with different functions can be analyzed according to different specification parameters.

- Output the analysis report in just one click, saving the time of taking screenshots manually.

- The report is easy to read and contains general reviews, images, coordinates, and other information.

Optimal tool for net tracing: Net tracer, Trace length, Line length, Via count details, Output report

Net Tracer is a useful tool that is applied to trace the relationship between PCB networks. It can integrate the relationship between CAD and components of the current job, as well as trace circuit signals from Net/Component at will. Besides, it can also keep tracing records and display the length of the trace.

-

Track all relevant nets from a component or Net instead of tracking manually.

-

Search a specific Component/Net/Pin by name.

-

The relevant component information can be found by clicking the signal line on the graphic interface.

-

The traced record can be saved automatically, showing the Trace length.

Browse all relevant component information

By selecting the component serial number, the component name, or clicking a component, the description and details of all the different components related can be obtained at a time. Automatically trace the line signal, and automatically calculate the trace length, via quantity, and drill depth.

Export Traced Summary Information

CAMPro enables to obtain all the relevant information, and automatically collects, organizes and outputs the report.

Net Tracer Demo Video:

Would you like to experience the power of Net Tracer?

Apply for CAMPro110 free trial now!

Copper Area Measurement tool

Copper consumption cost calculation, preventing plate warping due to uneven plate thickness

1. Calculate copper/gold usage rate: Evaluate costs in the design phase.

2. Consider copper thickness:

PCB Panelization Tool

Once the PCB area and the actual laminate have a size difference after the Layout engineer completes the PCB wiring, it will increase the unnecessary production cost. Therefore, before the PCB is put into production, the PCB will be put into panelization, using the plate with the best efficiency utilization, thereby reducing the production cost.

At present, the functions provided by the PCB design tools are mainly aimed at the circuit board design, but the layout requirements in the actual production and processing are not considered. Therefore, It is usually necessary to use different CAM software to deal with the problems and sometimes needs to choose whether or not to adopt a mirror board to lower the production risk.

On the other hand, if we deal with PCB layout design manually in a traditional way, it means a lot of work time, energy, and communication cost. Moreover, if the PCB design needs to be updated again, all the layout processes will have to be repeated again, which is quite a problem for engineers. Even worse, the delivery time will be delayed.

In order to optimize the panelization process, SYMMA Technology has designed a series of intelligent and automatic PCB panelization design tools, which can directly access the PCB design single board to deal with panelization design.

CAMPro provides features to customize the size of the substrate, the layout edge considering coupon simultaneously, and automatically calculates the optimal utilization rate of the substrate according to the size.

CAMPro PCB panelization tool offers various customized functions to apply to all situations and requirements of PCB panelization. If the PCB design changes, it can be synchronized through one click to help users to solve complex panelization issues so as to speed up the R&D process. CAMPro PCB panelization tool will definitely help you to optimize your work process.

Would you like to experience the power of Panelization Tools?

Apply for CAMPro220 free trial now

Gerber View

CAMPro enables Gerber to display graphically after automatically analyzing the file format.

Support File Format:

- Gerber RS-274X

- Gerber RS-274D

- ODB++

- IPC-2581

- IPC-D-356a

- Excel I / II

- DXF

Example of a Gerber graph:

Free Download: CAMProViewer