Design For Assembly (DFA)

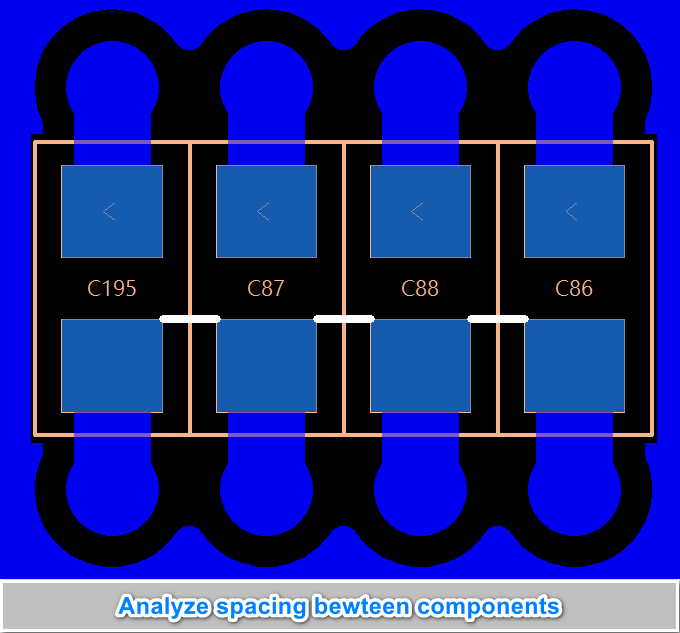

Assembly components are frequently the most time-consuming and expensive procedure in the PCB manufacturing process. The basic goal of PCB assembly is to attach the relevant components to the PCB board in a safe and precise manner. Therefore, in order to smooth the process, it’s crucial to determine whether the components are suitable for scheduled assembly.

If DFA is not used as part of the PCB design, it is very likely to cause problems in future circuit board assembly, such as prolonging the production cycle, increasing the cost, and unexpected tiny problems during the process from prototype to production.

As a result, before the data is delivered to the assembly plant, the key to ensuring successful PCB manufacturing is to perform the DFA analysis in advance.

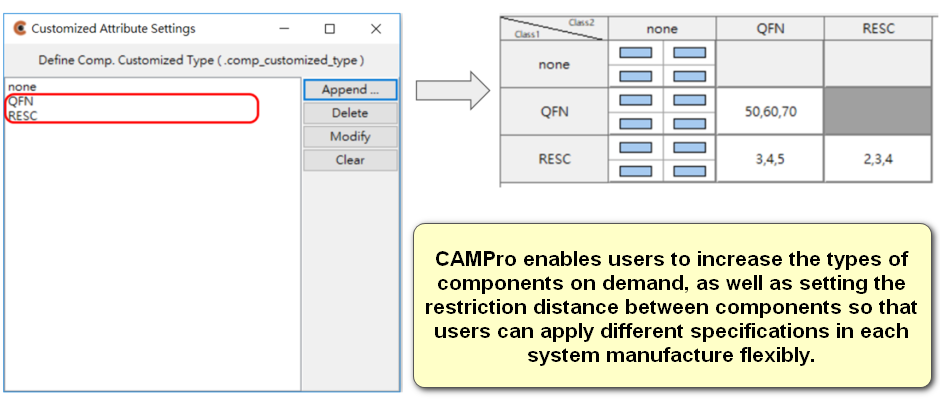

Since categories of a component are getting increasingly diversified, and some of the analysis items cannot be changed at any time. CAMPro provides the feature to customize component attributes.

Example: The distance between the QFN component and the resistance component must be kept at 5 mil, but the Comp to Comp test element cannot be expanded. How to measure these two parts in this situation?

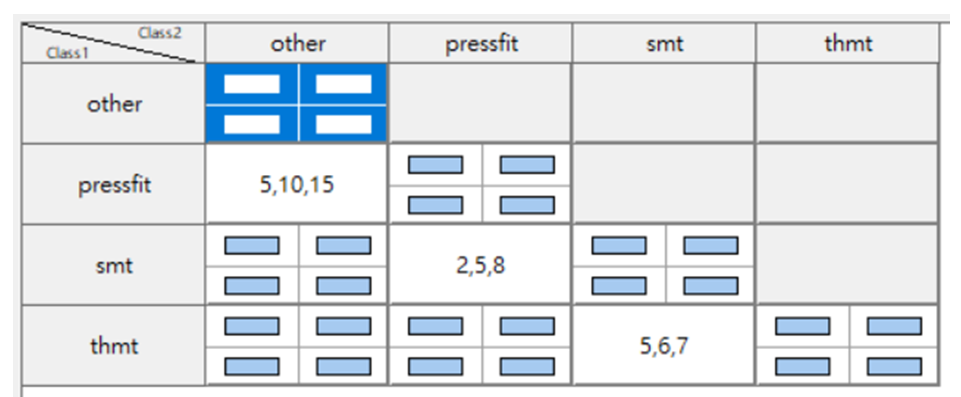

The fixed component category can not be applied to distinguish the varied component spacing:

CAMPro adopts cutting-edge technology of component verification to provide a complete assembly analysis tool for the PCB component assembly phase. Also, SMT assembly restrictions will be taken into account in advance, thus reducing the problem confirmation between the design team and the manufacturer. CAMPro directly automates the DFA analysis cumbersome process, providing accurate information, and automatically exporting professional analysis reports, thereby efficiently completing the entire assembly process.

Would you like to experience the Design For Assembly (DFA)?

Apply for CAMPro550 free trial now