Integrate with CAD Tool

Let CAD Tool integrate with CAMPro assist your design to achieve the optimal levels.

As the saying goes, “A workman must sharpen his tools if he is to do his work well.”, owning a high-efficiency automatic analysis tool will be your best strengthener for your PCB design.

After CAD Tool integrates with CAMPro, CAMPro will enable you to perform all kinds of analysis items in relation to PCB design, giving your PCB design a comprehensive analysis before putting into production and automating the cumbersome procedure instead of manual operation.

With CAMPro, PCB designer can further optimize and quickly prepare the required data for pre-production phase in a highly effective way to complete the task easily.

CAMPro enables CAD Tool to…

-

Synchronize screen image.

-

Perform a variety of scenario analysis in NPI (New Product Introduction) phase.

-

Complete PCB manufacturability analysis just by one-click.

-

Operate and edit on CAD Tool so you don’t even have to take time to learn how to operate new software.

Moreover…

-

Independent program by native graphic engine with faster processing speed.

-

Do not take CAD Tool resource, including the license.

-

Independent Graphic interface and database.

With the integration of CAMPro & CAD Tool, the most practical solution, shortens the design circle while reducing design costs and simultaneously optimize your PCB design!

CAMPro enables Gerber to display graphically after automatically analyzing the file format.

Support File Format:

-

Gerber RS-274X

-

Gerber RS-274D

-

ODB++

-

IPC-2581

-

IPC-D-356a

-

Excellon I / II

-

DXF

Example below:

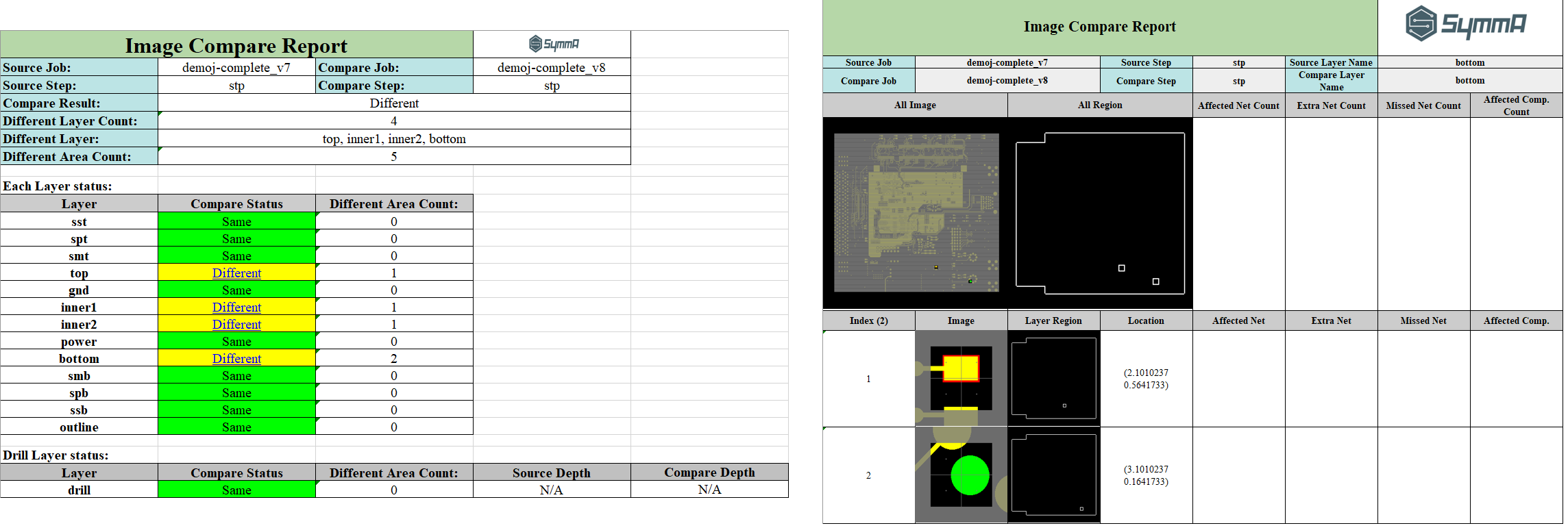

Gerber Version Compare

Optimal Version compare tool:Gerber Version Compare

Have you ever been through a loss caused by design error because Board File was modified without proper review mechanism?

Possible reasons would be…

-

There are no appropriate tools for engineers to compare different Gerber versions. Once Gerber versions update, engineers can only compare them manually.

-

Even if engineers have some tools, operation negligence still happens occasionally due to human error.

-

Comparison procedure is complicated and inspection cycle is tedious.

Are you exhausted by comparing different Gerber versions manually over and over again and looking forward to a better solution?

Let’s put an end to all these things via our brand-new module to solve your problems efficiently.

SYMMA Technology Co., Ltd. has released Gerber Version Compare module to offer the solution in relation to version comparison in an intelligent, efficient and easy-to-use way to smoothly solve your problems.

As the illustration shows that the differences will be highlighted visually.

You will benefit from…

-

Complete complicated comparison tasks with only one button.

-

Never decreases inspection frequency due to tedious comparison operation.

-

Integrate with CAD Tool without additional process of input and output data.

-

No more losses because of human error causing to rework or result in monetary loss.

-

Fast and simple browse interface, automatically output difference area report.

Gerber Version Compare in illustration:

Let go of complicated comparing version procedure and tedious inspection cycle manually. Embrace the brand new, time-saving and highly efficient automatic version compare tool.

Essential analysis for PCB Design — Netilst Compare

Have you ever been through incremental production cost because of Gerber Open/Short?

And situations as following:

-

Current tools are unable to confirm whether Gerber net is in good condition or not so you have to wait for PCB board manufacturer’s reply.

-

Although Gerber passed on Layout analysis, Gerber Open/Short still occurs in production occasionally.

-

Open/Short issues always happen urgently which affect your work and rest.

Are you tired of your daily work or even replying Open/Short issues after work all the time?

With CAMPro Netlist Analyzer, such issues will be solved easily once and for all.

Users will benefit from…

-

Quickly run the analysis to confirm the electrical consistency between Gerber and IPC.

-

Precisely browse report of Open/Short issues.

-

Complete analysis task with one button while you don’t even take time to learn new software.

-

Submit data in perfect safety.

-

No more unnecessary issues interrupt your schedules.

Fabrication Check

The optimal tool for PCB fabrication — Automatic DFM analysis.

Have you ever been through…

-

After Layout was submitted to PCB board manufacturers, what received from them is they were unable to produce it or you were informed a rise in the price for production.

-

Manufacture violates the design specification. For example, line becomes thinner, space becomes smaller which both result in exceeding the manufacturing process capability of the board manufacturer.

-

Problems suddenly were discovered in CAM analysis phase from board manufacture, affecting the new product launch plan.

If the problems are discovered until manufacture phase, it will be too late to save the situation and will cause monetary loss and waste time.

Research by IPC has shown that over 80% manufacturing defect is evitable during pre-production phase.

With CAMPro automated Design For Manufacturability (DFM) analysis, you will be able to prevent potential defects from happening.

CAMPro considers manufacturability of actual production and process based on design data, providing comprehensive manufacturability analysis before putting PCB into production.

What can be acomplished by CAMPro automatic DFM analysis?

-

Discover defect or deficiency of PCB design at the earliest time.

-

Ensure manufacturability to conform with PCB design specification.

-

Replace redundant manpower and decrease frequent communication at work.

-

Reduce the number of sample and trial production.

-

Accelerate time to launch new product to market.

-

Enhance product quality and increase your profits.

Assembly Check