DFF Analysis

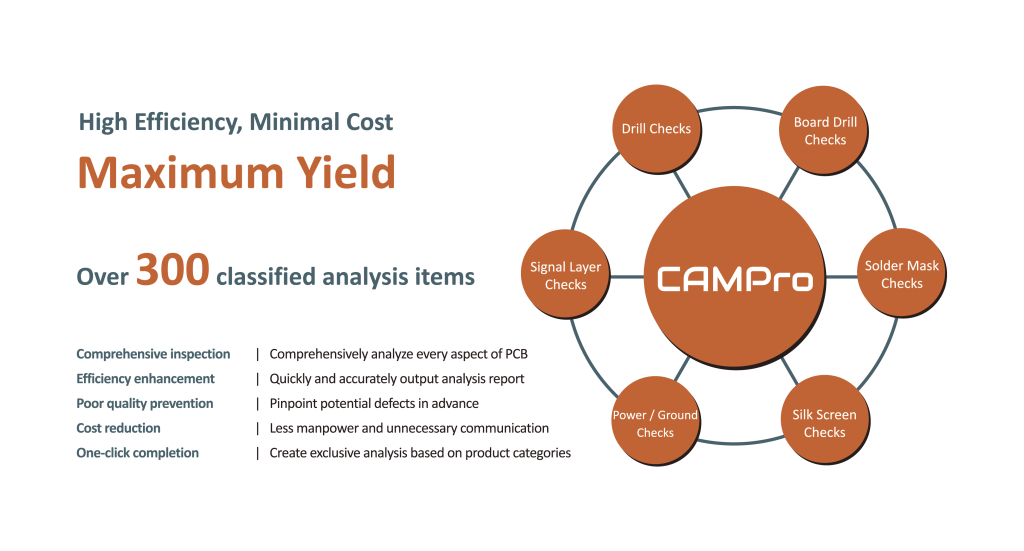

The best tool for optimizing PCB fabrication — Automatic DFF (Design For Fabrication) analysis.

Working in Have you ever been through…

- After Layout was submitted to PCB board manufacturers, what was received from them is they were unable to produce it or a rise in the price for production was informed.

- Manufacture violates the design specification. For example, lines become thinner, space becomes smaller, which both result in exceeding the manufacturing process capability of the board manufacturer.

- Problems suddenly were discovered in CAM analysis phase from board manufacture, affecting the new product launch plan.

If the problems are discovered until the manufacture phase, it will be too late to save the situation and will cause monetary loss and waste time.

Research by IPC has shown that over 80% manufacturing defect is evitable during the pre-production phase.

With CAMPro automated Design For Manufacturability (DFM) analysis, you will be able to prevent potential defects from happening.

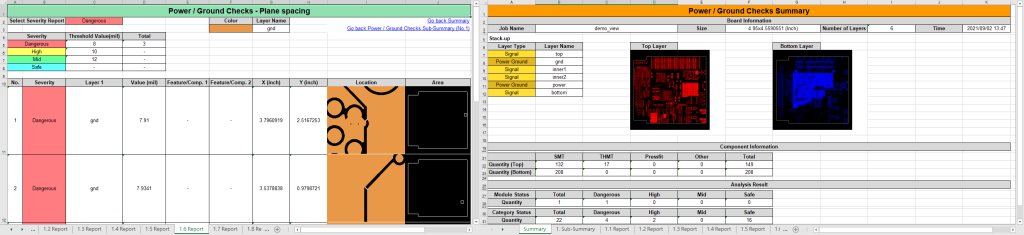

CAMPro enables one click to output reports to quickly summarize analysis results.

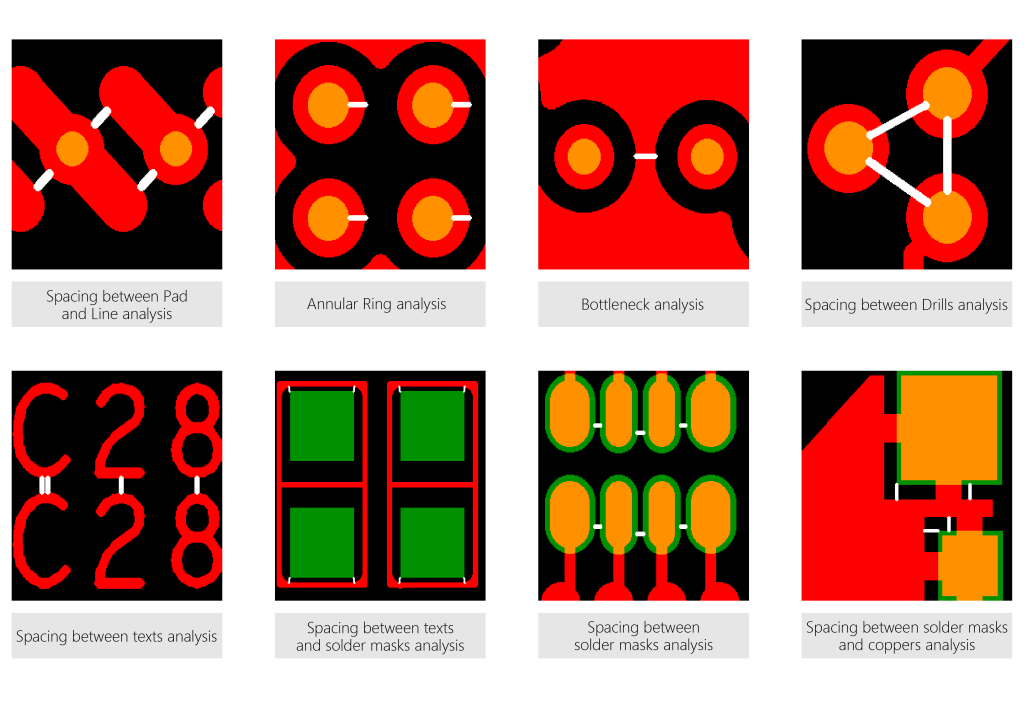

CAMPro considers manufacturability of actual production and process based on design data, providing comprehensive manufacturability analysis before putting PCB into production.

What can be accomplished by CAMPro automatic DFM analysis?

What can be accomplished by CAMPro automatic DFM analysis?

- Discover defect or deficiency of PCB design at the earliest time.

- Ensure manufacturability to conform with PCB design specifications.

- Replace redundant manpower and decrease frequent communication at work.

- Reduce the number of samples and trial production.

- Accelerate time to launch a new product to market.

- Enhance product quality and increase your profits.

Would you like to experience the power of DFF (Design For Fabrication)?

Apply for CAMPro 330 free trial now!